So the first week of mentorships at RSI are now well underway, and my research project is on CRUD. I should probably start from the beginning.

So I’ve been placed into the Short Lab at NW-13 on the MIT Campus, which is the heart of the Nuclear Science and Engineering department. My mentor is the fantastic Dr Michael Short, who just recently came back from Kazakhstan on some nuclear research collaboration and conferences. He brought back chocolate, which was a great way to start the week, assuring the staff and myself that it was indeed made from cow milk rather than camel milk (which apparently tastes “like a petting zoo”), and it’s probably not radioactive. To give you a sense of the vibe of the lab, my workspace is quite literally a red plush couch, and occasionally our various nuclear physics research is interrupted by spontaneous bouts of dart games, which can get quite competitive. Overall, I’m liking the place.

The short 5 minute walk from Maseeh dorms transitions quickly from urban university campus to industrial revolution era scenery on the way to the lab. All around are massive industrial structures with vague indication as to their nature, steam bellowing from pipes and towers and the unyielding chaos of renovation and construction everywhere. This is pretty jarring coming from the lush green lawns and ovals right outside Maseeh, but certainly makes for an interesting walk every morning. There’s always a guy on a segway zooming away with determination somewhere, or a group of students walking by talking about some crazy maths and physics theorems.

Once inside NW13 however, the science in the air hits you with full force. Up the stairs and into the beige corridors, I pass several posters on recent nuclear physics projects from the labs and closed doors with small windows peering into complicated machinery with big warning signs everywhere – “WARNING, RADIATION”. Then I arrive at the Short Lab. The day of scientific enquiry into the world of experimental nuclear physics begins.

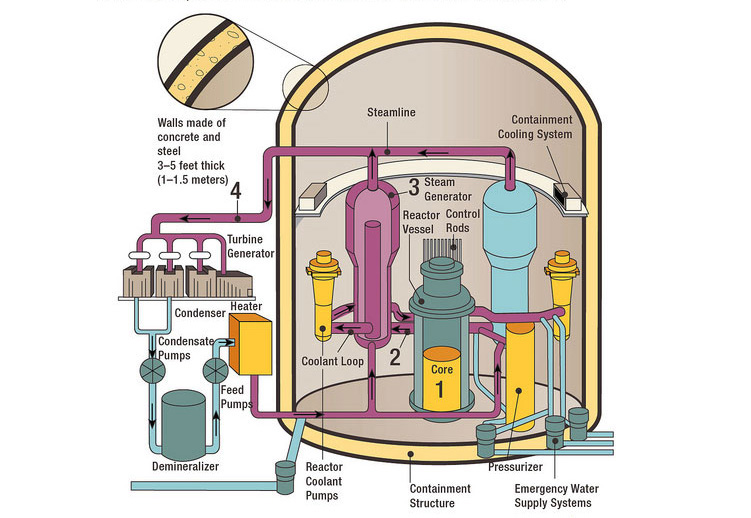

So by now you’re probably wondering what my research actually is, if you haven’t already heard. Well, essentially, it is on CRUD – Chalk River Unidentified Deposits…and specifically, materials that are resistant to it. So in all nuclear reactors – particularly Pressurized Water Reactors (PWRs) – due to the extreme conditions within the reactor chambers, ie. heat, pressure, radiation… the water (which has various other chemicals in it) tends to corrode the steel insides of the reactor.

All components are cladded with Zironium alloys (nicknamed Zircalloy) which corrodes over the fuel cycle of a reactor. This usually happens in the steam generator in which 80% of the surface area of a PWR resides due to the crazy looping of primary coolant tubes. Crud nanoparticles, such as Iron, Nickel, Copper and Chromium, then flow through the primary coolant and form a porous layer over all the interiors including fuel rods. This is kinda a big deal, because boron atoms within the coolant (which are neutron absorbant) get captured by the CRUD generating uncontrolled neutron flux, causing what is known as axial offset anomalies (AOA) and CRUD induced power shifts (CIPS). These are extremely bad news for the reactor, which as a result is more radioactive and therefore hazardous to the workers, generates less power and can sometimes even completely corrode cladding causing shielding failure. On average, a power plant will loose $1 million per day because of CRUD related problems. Furthermore, the US looses $14 billion a year because of costs associated with CRUD issues in nuclear power plants.

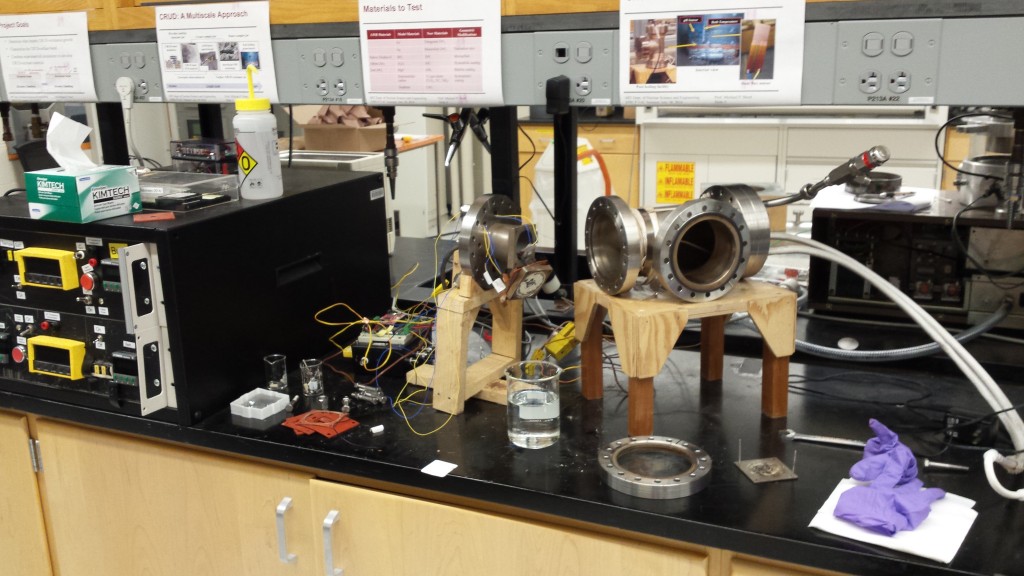

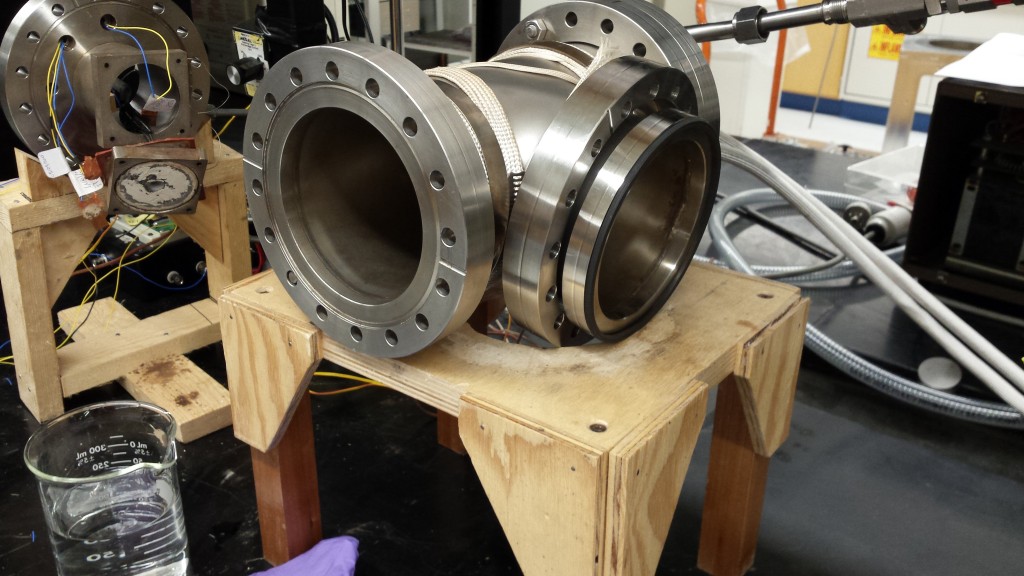

It’s a weird feeling to know that your research has a lot of significance and merit to it…that is if the experiment goes according to plan. Currently, the experiment will be to test 12 different materials and see which one performs the best under simulated reactor conditions (coolant water, high temperature, CRUD particles). Some of the materials I will be investigating include Zirconium Nitride, Zirconium Carbide, Zirconium Diboride, Titanium Carbide and Cerium Oxide. After the initial pool heating tests, the materials will then be examined using a 1nM resolution scanning electron microscope. And in conjunction with these tests, atomic force microscopy will see how resistant the material is against chemically bonding to existing CRUD particles.

So yeah, fun times ahead. I’m currently working on getting the experimental setup up and running, including calibrating pH meters, heat flux sensors and logomatic data collectors. Lots of hands on stuff.

Definitely looking forward to the weeks ahead.

-A

Leave a Reply